Axles and wheels are the backbones of a high-performing car, designed to ensure optimal grip, traction, and speed integrity. While learning their construction is not compulsory, it is highly recommended – especially for beginner drivers who have yet to understand how a car system functions.

My inclusive guidelines will smooth the learning process for you by detailing all major parts and names of a car wheel and axle.

In this article:

What Are The Labeled Parts of A Car Wheel And Axles?

A. Car Wheel Anatomy

1. Rims

Rims are a universal compartment of car wheels, keeping tires firmly in place and sealing them against external air to ensure proper PSI levels. That explains why flat tire issues tend to occur when drivers curb their wheels or get the rims damaged.

On another note, manufacturers usually mount tire balance weights on rims, especially when these wheels comprise steel sheets instead of standard aluminum.

See more: How Much Do New Rims Cost?

2. Barrels

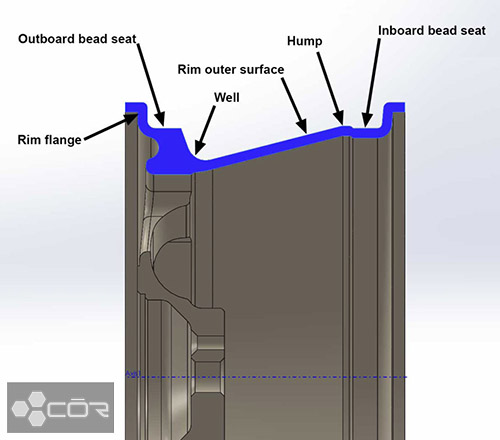

The next compartment is the “barrel,” referring to the wheel’s area between the inboard edges and outboard faces. Its primary aim is to offer an ample surface for tire mounting.

There are hardly any variations among wheel barrels from different brands, though in some exceptional cases, the position of its drop center heavily depends on the barrel’s width.

Still, as the drop centers barely affect any other design element other than mounting tires – drivers do not have to worry much about them. Investigating the wheel and barrel’s width only should be sufficient when scouring through wheel options.

3. Bolt Holes

As their names suggest, bolt holes are the wheel’s circular openings, where the bolts or studs pass across to latch the wheel securely onto the hub.

These holes are usually tapered to ball shapes or 60-degree angles. The latter is much more common, though certain reputed models like Honda, VW, and Audi do use ball seats.

For drivers seeking aftermarket wheels, remember to purchase bolts that match the wheels – not the vehicle. Using wrong-taper bolts is dangerous, which potentially causes the wheels to get loose and fall off.

4. Bolt Patterns

Let’s delve into the most critical part: the bolt patterns. Without correct patterns, installing new wheels onto cars will be almost impossible.

For instance, a 4×100 pattern means the tire has four bolts, each of which is located about 100 millimeters apart from the opposite bolt (measured from the hole’s center). Other variations, such as 4×108 or 4×98, also exist.

8-bolt and 6-bolt wheels have the same pattern measurements (the number of holes x distances between opposing bolts).

Meanwhile, 5-bolt wheels have no opposing bolts. Hence, experts would calculate the distance from a bolt to the midpoint of the two opposite bolts (meaning you have to visualize an imaginary line between 2 holes and find the center point).

5. Center Bore

Another critical feature is the wheel’s center bore – a circular opening of the wheel’s center. (Do not mistake it for bolt holes, as the latter are located around the wheel’s perimeter, not the center).

Be careful during the mounting process: if the center bore has larger diameters than wheel hubs, the bolts might have to carry the entire vehicle loads.

Some people assume that is what these bolts are made to do, but they aren’t; bolts only help sustain stretching/tension forces when cornering.

So wrong setups will hamper the bolt’s ability to handle bending forces, ultimately breaking amidst your drive. And losing wheels on highways isn’t fun at all.

6. Spokes

Each wheel assembly arrives with spokes, thin metal, thin rods radiating from the wheel’s center hub to connect with outer rims. They provide a structural base for the wheels while distributing the car’s weight more evenly.

These spokes are what drive people to purchase aftermarket wheels; their classy and expensive polishes boost the car’s luxury tenfolds. Provided the center bores, bolt patterns, and sizes are a perfect fit for the vehicle, its designs are entirely up to your preference.

If desired, you may hollow the spokes to reduce unsprung weight. Still, that is unnecessary, as such minimal weight reductions are only significant on special occasions (ex: race tracks). Regular driving will not benefit much from these tactics.

7. Tires

Of course, the whole point of a wheel assembly will be non-existent without car tires. With their ring-shell shape, tires protect the wheel’s inner parts behind thick layers of synthetic materials, carbon black, and rubber.

Besides, since tires have direct contact with the terrain, their prioritized function is minimizing shock. They cushion bumpy and rough road surfaces to keep cars from further damage.

For more:

8. Valve Systems

The title is self-explanatory: valve systems monitor the tire’s deflation and inflation. They are constructed from three main parts:

- The cap and the core cooperate to seal tire air

- The extension adjusts the PSI (pressure) accordingly

9. The Wheel Bearings

Wheel bearings serve as the actual link between a car’s wheel and axle (which we will delve further into the latter sections).

As they carry the vehicle’s weight directly in drives, wheel bearings have always been vulnerable to damage. Hence, screwing them tightly onto the hub is a must; otherwise, road elements may invade and tear internal compartments apart.

10. Beads and Flanges

See those funny edges poking out of the tires? They are axle flanges, and inside them are the beads. Together, the two keep your vehicle stable upon challenging terrains, adequately transferring motor energy to the wheels.

Should any damage be inflicted on either of them, the energy transmission will suffer, leading to car instability and violent shaking.

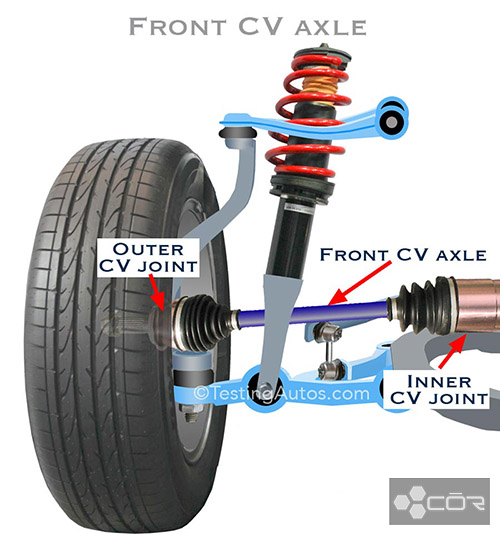

11. CV (Constant Velocity) Joint

CV joints – the connector device between the transmission and wheels are comparable to joints in human bodies. They transfer transmission torque to the wheel, keeping cars at their constant velocity( true to their name) during sharp turns.

As a result, the automobile can move and relocate its limbs without hassles – like how we use our arms and legs. That, in turn, lets the tires rotate in full circles, offering smooth and efficient power control.

12. Outer Lip

Also called “rim lip,” an outer lip is the furthest, outermost wheel edge that touches the tire. Here, the wheel seals against the beads to bind the tires firmly in place.

Since it lies on the outside portion, the outer lips will likely break down whenever the wheels strike a pothole or hit a curb. Thankfully, they are easy to repair and replace.

13. Wheel Fasteners

Wrapping up our diagram is the wheel fasteners, tightening the rims to the axle flange or hub. Although there are different wheel fasteners, wheel studs’ popularity surpasses most. These studs are usually pressed into the flange and hub for a more secure union.

Manufacturers often create stud heads bigger than the holes to keep them from piercing into the flanges. Also, the hub/flange’s center is slightly elevated to the rim’s center to give the wheels more balance.

B. Parts of An Axle Assembly

Axle is what holds/connects wheels/tires to the car. Let’s see what makes up this part.

1. Subframe

Set up below the engine, subframes serve as mounting points for the lower and upper control arms. They also hold the transmission and engine in place for FWD (front-wheel drive) vehicles.

2. Lower and Upper Control Arms

Both arms are attached to the suspension at one end and the subframe at another.

Their design purpose is to guide the upward and downward movements of the wheels and suspension. Due to this fixed construction, they do not allow back-to-front or sideway wheel rotation.

3. Half-Axle

The half axles are set up on all RWD, FWD, and AWD cars. Their primary functions are straightforward: transferring rotational movements from the transmission or engine to the wheel.

Each axle end holds one CV joint (as introduced above), allowing drivers to steer and move the wheels upwards/downwards while their axles rotate.

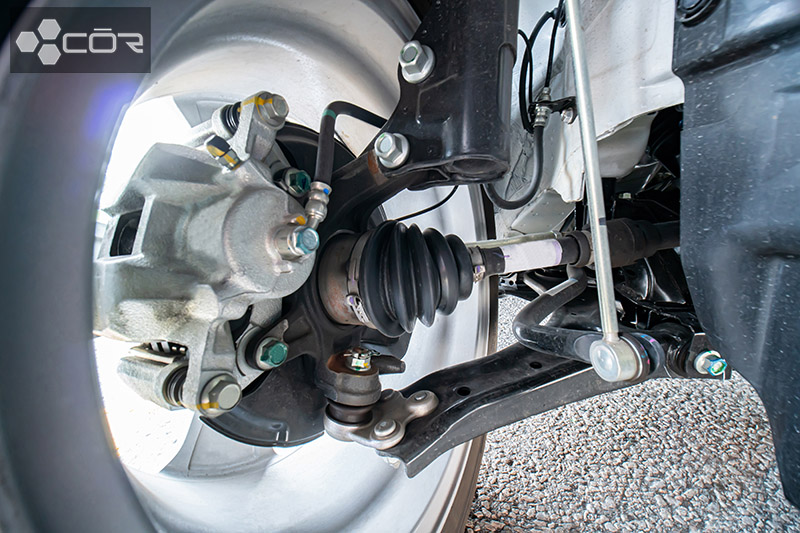

4. Strut Assembly

The springs and struts are sometimes separate in certain suspension and vehicle types.

Despite installment variations, their purposes remain: to provide a smooth, no-bump drive. Without the struts to control vehicle movements and the springs that support its weight, your car would keep bouncing through the entire road.

5. Brake Assembly

A typical brake assembly comprises three fundamental components: the brake pads, calipers, and brake discs.

- Brake discs rotate along with the axle and the wheel.

- Brake pads and brake calipers are set up to support your suspension assembly.

When the brakes are applied, the calipers will squeeze the pads into rotating discs, resulting in appropriate friction to slow the car down.

6. Steering Knuckles

Every suspension component I have mentioned above (brake assembly, strut, control arm, etc.) is attached to these knuckles. They enable the car’s front tires to veer right and left, changing directions as you please.

7. Sway Bars

Sway bars connect suspension assemblies together on the axle and mount upon lower control arms. This design limits free movements between suspension and wheel systems, resulting in a more stable car and fewer rolls at corners.

8. Steering Rack and Tie Rod

When the rack converts rotational input from steering wheels into linear moves, two tie rods stick out of the rack’s ends, pushing out to the right or left (depending on which direction your car turns) and moving the wheels forward.

9. Transfer Case

A critical axle element, transfer cases are slotted between the front and rear. They are also backed up by the transmission and driveshafts (which I will return to later).

Transfer cases transfer energy alternatively to and fro the front and rear, ensuring proper power balance. They are particularly helpful when your car drives on highways.

10. Gaskets

Despite the small size (the smallest axle part, in all honesty), only novices would dare underestimate their functions.

Gaskets are the last puzzle piece to complete to secure the union of driveshafts, differentials, housings, and transmissions. Without them, smooth rides will never be feasible.

Plus, gaskets also seal the gearbox liquid to control fluid leakage, which might otherwise cause irreversible internal defects to the transmission and differentials.

11. Driveshafts

The automobile industry introduces two driveshaft types: short CV and propeller shafts.

Both are identical in functions, working with each differential to transfer energy back and forth to the front and rear axles. The only difference mainly lies in their mounting positions.

12. Differential

This axle compartment is responsible for handling car balances when the back and front wheels rotate at significantly different speeds.

Aided by multiple gears (ring and spider gears, for instance), they ensure both axles receive proper support and steer clear of skidding/slipping accidents.

13. Axle Housing

As its name implies, axle housing stores most of the axle components. Hence, it comprises durable, sturdy metals that easily withstand all road conditions.

The housing box is linked to the remainder of the vehicle by strong axle bearings. That way, every compartment stays stabilized while driving.

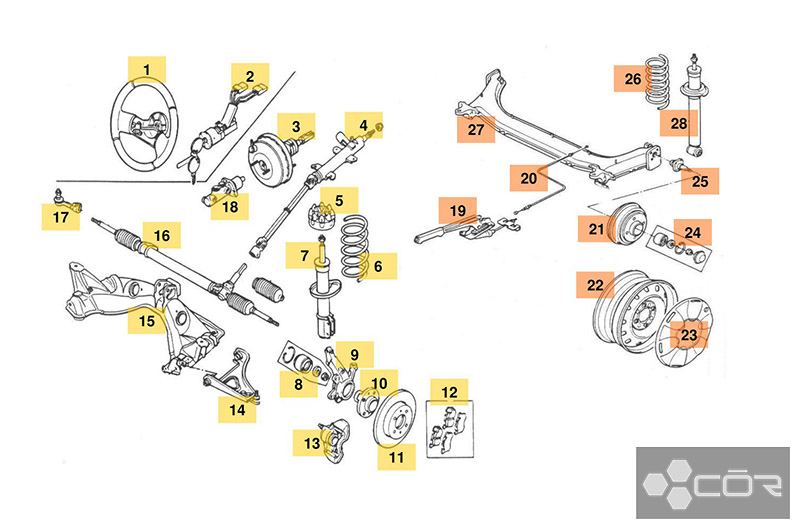

Here are the full parts of an axle assembly:

| FRONT AXLE ASSEMBLY | REAR AXLE ASSEMBLY | ||

| 1 | Steering wheel | 19 | Handbrake lever |

| 2 | Ignition switch | 20 | Handbrake cable |

| 3 | Brake servo (brake booster) | 21 | Brake drum |

| 4 | Steering column | 22 | Road wheel |

| 5 | Front shock mounts | 23 | Hubcap |

| 6 | Suspension spring | 24 | Rear wheel bearing |

| 7 | Front shock absorber | 25 | Rear stub axle |

| 8 | Front wheel bearing | 26 | Rear suspension spring |

| 9 | Front steering knuckle (or hub carrier) | 27 | Rear axle |

| 10 | Hub | 28 | Rear shock absorber |

| 11 | Brake disk | ||

| 12 | Brake pads | ||

| 13 | Brake callipers | ||

| 14 | Lower wishbone | ||

| 15 | Subframe | ||

| 16 | Steering rack | ||

| 17 | Tie rod end | ||

| 18 | Brake master cylinder | ||

What Are The Different Types of Axles?

The diagram above has already mentioned some standard axle types while introducing each axle part. For those who have not caught it, though, here’s a quick summary:

- Rear axle: Transmitting power to driving wheels. It has two halves (or half shafts) connected by a differential. On most vehicle models, rear axles will rotate together with the wheels.

- Front axle: Assisting with shock processing and steering on uneven surfaces. Sturdiness, hence, is strongly required, which explains why they are made from durable materials like nickel steel or carbon steel.

- Stub axle: Located at the front wheels, stub axles bind all these axles together via kingpins.

What Are The Different Types of Car Wheels?

Car wheels (aftermarket ones not counted) are generally categorized into six types:

- Steer wheel (or Steelies): manufactured from steel billets and hydraulic machinery.

- Alloy wheel: made of magnesium and aluminum.

- Multi-piece wheel: comprising 2-3 more components than their basic counterparts to deliver more adjustability and freedom.

- Chrome wheel: coated in chrome finishes to avoid corrosion.

- Diamond-cut wheel: Similar to standard alloy wheels but with a higher-shine finish. Manufacturers employ machine lathes for metal incisions, producing shinier glosses and grooving effects.

How Long Do Wheels And Axles Last?

Both the axles and wheel assemblies can last 10 years or even more – but only when well-maintained. Otherwise, symptoms of defects may arrive sooner than that due to corrosion, scraping impacts, or underinflated tires.

Keep an eye out for the following signals to fix your vehicle before it’s too late:

a. Symptoms of bad wheels:

- Grating or grinding noises from the tires or wheels

- Car looseness / slower responses

- Car veering to the side

- Uneven wear

b. Symptoms of bad car axles:

- The car does not budge after revving

- Strained gas pedals

- Sputtering noises

- Wheel vibrations and wobbling

- Braking pad misalignment

- Small oil leaks on brake drums and CV ball joints

Conclusion

Hopefully, my detailed guidelines for the car’s drive axles and wheels can clear up confusion and misunderstanding for beginners. You may search other Youtube videos and illustrations to gain a better visual overview, and feel free to write to me if anything does not add up.