Tire treads are a critical compartment in every automobile, especially high-quality cars. It’s hard to imagine how you can manage the system control with worn tires that keep shaking and vibrating! Unfortunately, most drivers tend not to notice their bald tires until too late.

So how to avoid such disasters? The best bet is to constantly check on your tires using simple methods – such as a tire penny test. Keep scrolling for more guidance and tips on how to carry out a penny tire test.

What Is Tire Tread and Tread Depth? Why Measuring It Is Important

1. Tire Tread and Tread Patterns

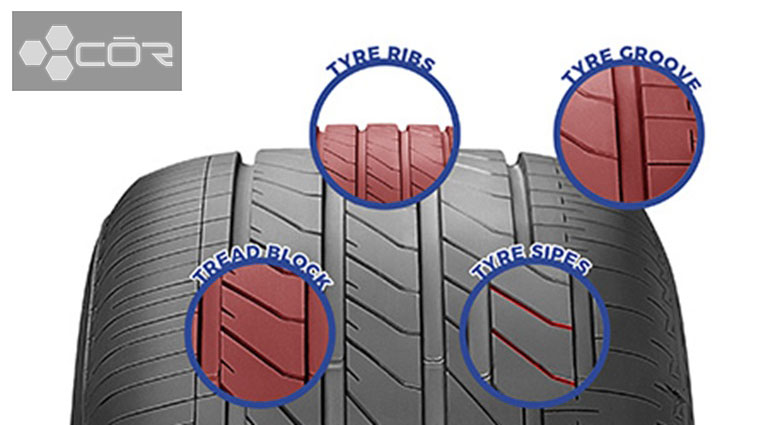

The term “tire tread” refers to a tire’s circumference rubber that directly contacts your driving terrain (ex: mud, road, etc.). A typical tire tread consists of four main parts, including:

- Ribs: The raised bands wrapping around the tire

- Blocks/lugs: The elevated segments in the gaps between ribs. Together with the tread ribs, they hit the road surfaces during your car’s operation.

- Grooves: the gaps between car ribs

- Voids: the distance among tread blocks. Voids and grooves channel water whenever the roads are flooded, allowing the blocks and lugs to move/flex easily

Tire manufacturers strive to combine all four, creating a signature design that promises long-time tire performance for every driving condition and weather.

Though each brand has its unique take on the tread, the common patterns can be divided into three groups with different efficiency and handling:

- Symmetric: the same patterns are spread across an entire tire, which is extremely popular for passenger vehicles.

- Directional (Least durable/easily worn-out): The patterns (lateral voids included) point to one direction in a V structure. This design thrives in performance cars (where speed is the priority).

- Asymmetric (Most durable): This version combines both directional and symmetric designs to work well all year round (dry/winter conditions).

2. Tread Depth

When someone says “tread depth,” they are referring to the vertical measurement from the rubber’s top to the deepest grooves of the tire’s bottom. The most common estimation for tread depth is based on 32-nds of one inch.

Please note that tire parts will be considered “worn out” once they touch 2/32” of the remaining tread. By illustration, a standard type with an original depth of 10/32” only has 8/32” usable tread.

3. Why Measuring Tire Tread Is Important

Needless to say, tire grips form a tight bond between the car and the road. Hence, if the tread depth is less than satisfactory, the vehicle will lose traction in a blink and suffer from extended braking.

Worse, your failure to tend to shallow grooves (especially in directional-pattern tires) will be the perfect formula for disasters in wet conditions, increasing the risks of aquaplaning.

How to Check Tire Tread With A Penny?

This guide will use the U.S. penny as our main measuring tool. For those living in other countries or not having a U.S. penny, feel free to pick other alternative coins.

Step 1. Make Sure The Penny Is Clean

Dig around your coin jar, purse, or wallet for a shiny and clean penny. And what if it’s too dirty? Wipe it with a soft, dry cloth; otherwise, getting an accurate result will be difficult.

Step 2. Rotate It And Point Abe’s Head At The Car Tire

Turn your penny around to get Abraham Lincoln to face you directly, with his hair pointing down the tire’s center. For people using quarters instead of pennies, do the same with George Washington’s profile.

Step 3. Slide That Penny Between Tire Treads for Measurements

Tire treads are the biggest groove at the center, wrapping in parallel to a tire’s side rubber. A car usually has many threads, so choose any you like and slip the penny between them.

Ensure the coin’s edge rests straight against the tread’s space, and keep Abe’s hair pointing to the tire’s middle.

Do not fret about whether you should do it from the top or side of the tires. Pick any spot you like, as long as the penny can be observed in plain sight.

Step 4. Observe: How High Can The Rubber Reach Abe’s Portrait?

Pay attention to where the sticking rubber (that goes past the coin’s side) sits against Abe. It will help you estimate the general worn-down rate of the tread.

Step 5. Check The Other Tread Parts of That Same Tire

After noting the connection point between the coin and the rubber, pull your penny out and repeat the above steps to the other 2-3 tread lengths on that tire.

If necessary, do it again for the tire’s other side to check for inconsistencies. ALWAYS remember to make Abe’s hair point to the rim’s center every time you perform a new check.

Step 6. Interpret Your Findings

Can you see Abe’s head top while the penny is deep in the treads? Time to have your tires replaced at tire shops.

And what if the penny sinks deep into the treads where tire rubbers meet Abe’s eyes, completely covering his hair? Then you can keep driving.

The Pros and Cons of A Penny Test

Penny tests are extremely common, but are they perfect, though? Have a look at some of their pros and cons:

Pros

- Quick and cheap

- Easy to carry out

- Can be pretty accurate in many cases

Cons

- Occasional inconsistencies (some tire parts fail the test while others pass).

- It does not always reflect the legal requirements for tire treads. (ex: certain areas require tire replacements when less than 2/32” tread is left; others 3/32”, 4/32”, and so on)

Is Penny Tire Test Accurate?

Yes. Despite some concerns about inconsistencies, you can be confident that their readings are mostly accurate.

However, for people who do not feel confident in their measuring skills – or have no U.S. penny around for usage – you might have to double-check the results with other tools.

Other Alternatives to Check Tire Tread Other Than Tire Coin Test

- Using Rulers: Measure the tread lines on a 1/16” scale (1/16” equals 2/32). It’s also a pretty accurate method, though some complain that sticking the ruler between the tread grooves can be difficult.

- Using Tire Tread Depth Gauges: The best and ultimate option to ensure NO misreadings or mistranslations can occur. You do not have to calculate or estimate anything, either, since this tool is already marked in an inch’s 32nds. Simply slip it between the treads to determine how much tread depth remains.

Conclusion

We hope that this inclusive guide on using pennies for tread tests has cleared up all confusion. Do not forget to carry out this test at least once a week!

Of course, if more help and support are still required, feel free to write to us.

You might also like these articles: