It is rare to see people questioning how tires are made; the common assumption is that they comprise mostly rubber.

I have some surprises for you: there are more substances in a standard tire than one would think! Keep scrolling through my guide to learn more.

In this article:

What Are Rubber Tires Made Of?

Tires contain a majority of rubber (both natural and synthetic) along with other components like steel/heavy metals, textile, fillers, and antioxidants. The list extends to as many as 25 materials and varies depending on the manufacturers.

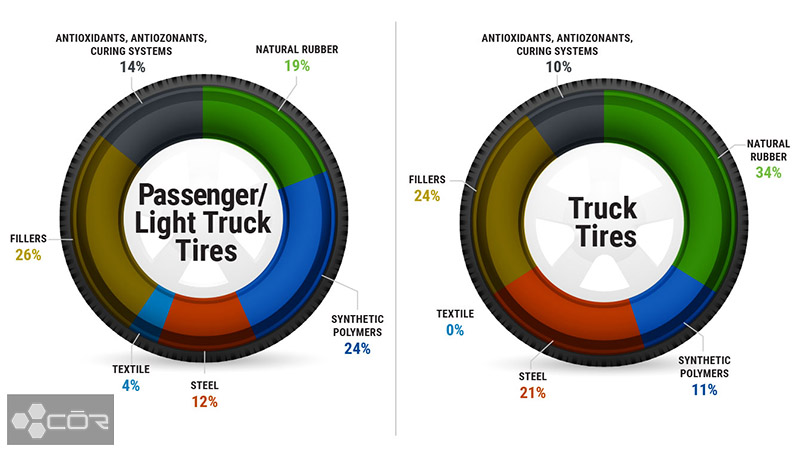

1. Natural Rubber

Light tires: 19%

Heavy tires: 34%

Rubber provides basic, standard performance characteristics for the tires; even non-expert can tell their tires are made from this classic material. After all, its fatigue and tear crack resistance have always been globally recognized.

2. Synthetic Rubber Polymers

Light tires: 24%

Heavy tires: 11%

The largest tire manufacturers mostly adopt two synthetic rubber polymer types: Styrene-butadiene and Butadiene, used in a mixture with regular/natural rubber.

Together, their chemical and physical properties determine tire components’ performance, such as traction, wear, and rolling resistance.

In the case of higher-end, shredded tires, you can also find another synthetic rubber, Halobutyl (or Halogenated polyisobutylene). Thanks to Halobutyl, the tire’s inner liner becomes impermeable, allowing the solid tire to stay inflated.

3. Steel/ Heavy Metals

Light tires: 12%

Heavy tires: 21%

One can find steel wires in tire beads, belts, and plies (heavy clincher tires):

- The tread and belts stiffen your tire casing to improve handling and tire wear performance

- The beads and plies anchor and lock the scrap tires firmly in place.

4. Textile

Light tires: 4%

Heavy tires: 0%

“Textile” refers to various fabric cord types that reinforce and strengthen the tires, providing weight support and ample dimensional stability. Some of the popular textile fabrics are:

- Polyester cord

- Rayon cord

- Nylon cord

- Aramid cord

These cores reinforce the casing material, maintain the tire’s shape on different terrains and road conditions, and provide extra endurance capabilities for light passenger car tires.

Meanwhile, since heavy tires already excel in endurance, they do not need textiles the same way light tires do.

5. Fillers (Amorphous Silica, Carbon Black)

Light tires: 26%

Heavy tires: 24%

Both silica and carbon black are fillers used to reinforce the natural rubber, improving its major properties like abrasion, tensile strength, and tear. As a result, the car’s traction, rolling resistance, and tire performance enjoy a tremendous boost.

6. Antioxidants, Antiozonants, and Curing Systems

Light tires: 14%

Heavy tires: 10%

- Antioxidants

Actual rubber compounds tend to break down from oxygen/temperature exposure and heat sources. Antioxidants are included to prevent that from happening – or at least slow down the process.

- Antiozonants

As their name suggests quite clearly, antiozonants are included to reduce the impacts of ozone exposure to the tire’s surface. Cracking and deteriorating rates will be slowed down, extending the tire’s shelf life and overall sturdiness.

- Curing Systems (Zinc Oxide, Sulfur)

Wrapping up the list is zinc oxide and sulfur, crucial elements to change natural rubber into solid articles during tire curing or vulcanization. These materials speed up the vulcanization process while improving the crosslinks’ quality and quantity in the matrix rubber.

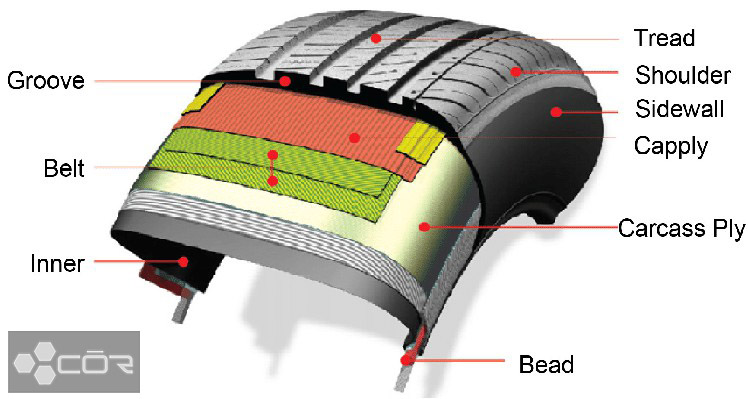

What Is The Basic Tire Structure?

Now that we have settled the ingredients used by tire factories, I will discuss the basic automotive tire structure in more detail:

1. The Tread Pattern: The outer tire layers, envelop the casing to provide great gas mileage, optimal handling, and reduced rolling resistance. More specifically, a tread design comprises:

- Cap: the tire part that has the most frequent contact with the road surfaces

- Base: below the cap, reducing damage and rolling resistance

- Shoulder: on the tread’s outer edges, where optimal tread-sidewall transition points are formed.

- Cap Plies: Directly underneath the tread depth, enabling high-speed traveling

- Steel belt plies: Steel cords that enhance directional stability, shape retention, and frictional interaction of tire.

2. The Casing: The casing/carcass is the tire’s interior areas, functioning like inner tubes that contain air and cushion the entire tire. It continues to be broken down into:

- Textile plies: containing the tire’s internal pressure to avoid flat tires, both in humid and dry conditions.

- Inner liner: sealing the air chamber and increasing fuel economy

- Sidewall: protecting the prepared casing against atmospheric conditions, environmental impacts, and external damage.

3. Tire Beads: Connect the wheel to the tire to ensure they are both bound firmly in place. There are three major parts:

- Bead reinforcement: comprising aramid or nylon to improve steering response and fuel efficiency

- Bead apex: offering extra steering comfort through the synthetic rubber wedge

- Bead core: the bead’s center, made of steel embedded inside the rubber. Without it, the tire cannot sit on your wheel rim firmly.

What Is The Tire Manufacturing Process?

As I have already given you a full ingredient list, it is quite easy to visualize the entire tire production:

Step 1. Mixing the ingredients (listed above) to create compounds.

Step 2. Push the rubber through the dies to solidify the tire sidewall and tread shapes.

Step 3. Press the rubber into the breeding ground, manifesting a rubber-coated sheet that can be cut into industrial tire components: steel belts, body plies, inner liners, etc.

Step 4. Wrap the compound around a sturdy drum, then use tire pressure to force them together. We have a green tire at this point – meaning it hasn’t been properly cured yet.

Step 5. Cure the automotive tires with bladders, gas fills, tire contact patch, steam, leaching of metals, etc.

FAQs

Why Are All Modern Tires Black?

The carbon black is used to stabilize the chemicals of the industrial tires, hence the color.

Can You Put Water In A Modern Tire?

No, regardless of tire sizes and types. Radial tires filled to the brim with water will suffer serious damage and grip loss, impacting the car’s entire performance. Flat tire issues are inevitable.

Conclusion

Tire construction is quite complex, and many ingredients combine to optimize its performance. Though varying among tire brands, rubber is always the foundation, accompanied by other materials to form a solid tire.

See more: